Industries worldwide rely on various mechanical systems to drive efficiency and productivity. Among these, water turbines, turbine service units, fans, and compressors are critical components. Additionally, the need for specialized training in operating and maintaining turbines is growing as technology evolves. This article explores the importance, functionality, and maintenance of these systems, along with the value of training programs.

Water Turbines: Harnessing Renewable Energy

A Water turbine is a device that converts the kinetic energy of flowing or falling water into mechanical energy, which is subsequently transformed into electricity. These turbines are vital in hydropower plants, contributing significantly to renewable energy production. By using water as a resource, they provide a clean, sustainable alternative to fossil fuels.

Types of water turbines include Pelton, Kaplan, and Francis turbines, each tailored to specific water conditions. For instance, Pelton turbines are ideal for high-head, low-flow environments, while Kaplan turbines perform well in low-head, high-flow situations. Their efficiency and adaptability make water turbines essential in the global shift toward greener energy solutions.

Turbine Service Units: Ensuring Peak Performance

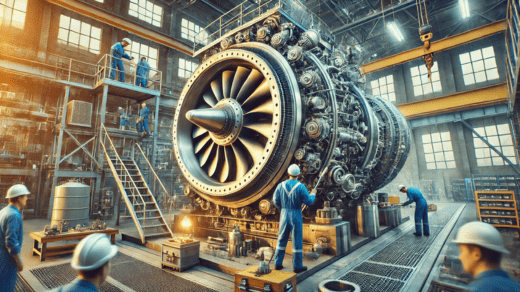

A turbine service unit plays an essential role in maintaining the functionality and efficiency of turbines. Over time, turbines can experience wear and tear due to continuous operation, exposure to environmental factors, and fluctuating loads. Regular inspections and timely repairs are necessary to keep them running smoothly.

Service units are equipped with tools for diagnosing, repairing, and optimizing turbines, ensuring minimal downtime and extended operational lifespans. They handle everything from blade inspection and thermal coatings to shaft alignment and performance testing. By investing in high-quality turbine service units, industries can reduce energy losses and increase reliability.

Fans and Compressors: Industrial Powerhouses

Fans and compressors are fundamental to industrial and commercial operations. Fans ensure proper ventilation, cooling, and air circulation in systems such as HVAC, exhaust setups, and process cooling. On the other hand, compressors are crucial for increasing the pressure of gases, enabling their use in refrigeration, pneumatic tools, and even energy storage.

These systems are indispensable in sectors like manufacturing, oil and gas, and power generation. Proper maintenance of fans and compressors is vital to prevent inefficiencies, maintain safety, and extend equipment life. Neglecting their upkeep can lead to operational disruptions and increased energy consumption.

Training Turbines: Building Expertise for the Future

The complexity of modern turbine systems has made training turbines an essential part of workforce development. Training programs offer hands-on experience, enabling technicians and engineers to understand turbine design, operation, troubleshooting, and safety protocols.

These programs often use simulators and real-world equipment to provide practical knowledge. By equipping personnel with the skills to handle advanced turbines, industries can reduce the risks of operational errors, improve safety, and optimize performance. As the demand for renewable energy grows, so does the need for skilled professionals who can manage and maintain turbine systems effectively.

Conclusion

Water turbines, turbine service units, fans, and compressors are vital components of modern infrastructure and industry. ttraining turbines Their proper maintenance and operation ensure sustainability, efficiency, and productivity. Furthermore, investing in training turbines and workforce education empowers industries to stay competitive while promoting a safer, greener future. By focusing on these critical systems, industries can meet both current and future challenges with confidence.